Paddy Drying Solutions

We are experts is Grain Dryer technology. No matter what crop you are growing or where you are farming we can provide a solution that will work for you. We provide professional service and installation on a variety of setups including custom-designed permanent installations models in numerous sizes. Drying Solutions

- Minimum Maintenance

- Low Energy Consumption

- Flexible Modular Constructing

- Large volume capacity available

- Easy access throughout for inspection purpose

- Extremely user friendly controls

- Remarkably gentle processing of the grain

- Optimum energy savings by circulating air and heat recovery

- Scientifically fitted finned tubes provides, no heat loss

- High performance fans and air heating technology

- Highest quality material ensuring long life

- Uniform product moisture by modern discharge technology

- Suitable for indoor and outdoor installation

Quick and steady moisture removing without hurting paddy quality.

Dryer Advantages

Flexible Capacity

Additional dryers could be added based on the capacity demand, save investment cost, Also, expansion in width and height is possible by pre-designing for future expansion. That can be handle small or high volume, from few tons to thousand tons a day, great flexibility.

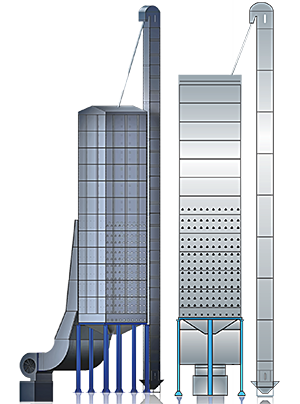

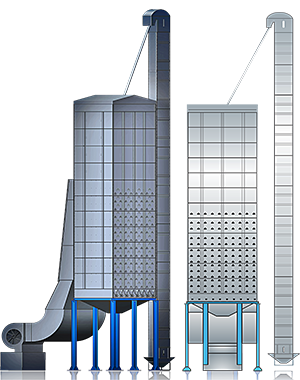

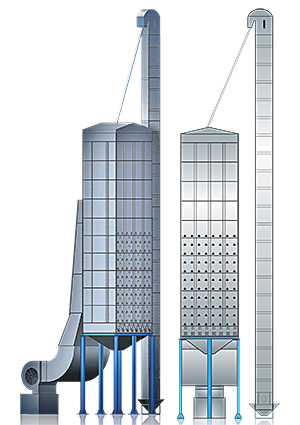

Unique Design

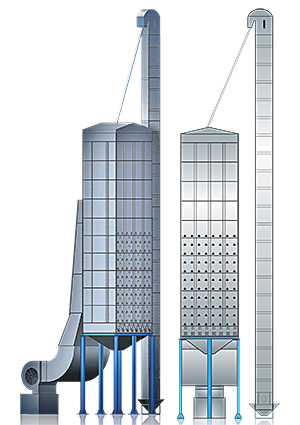

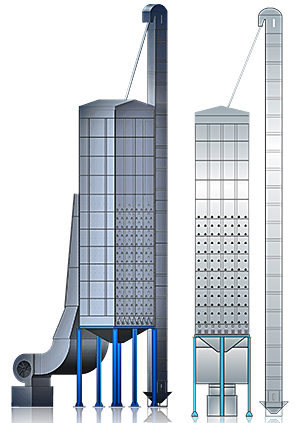

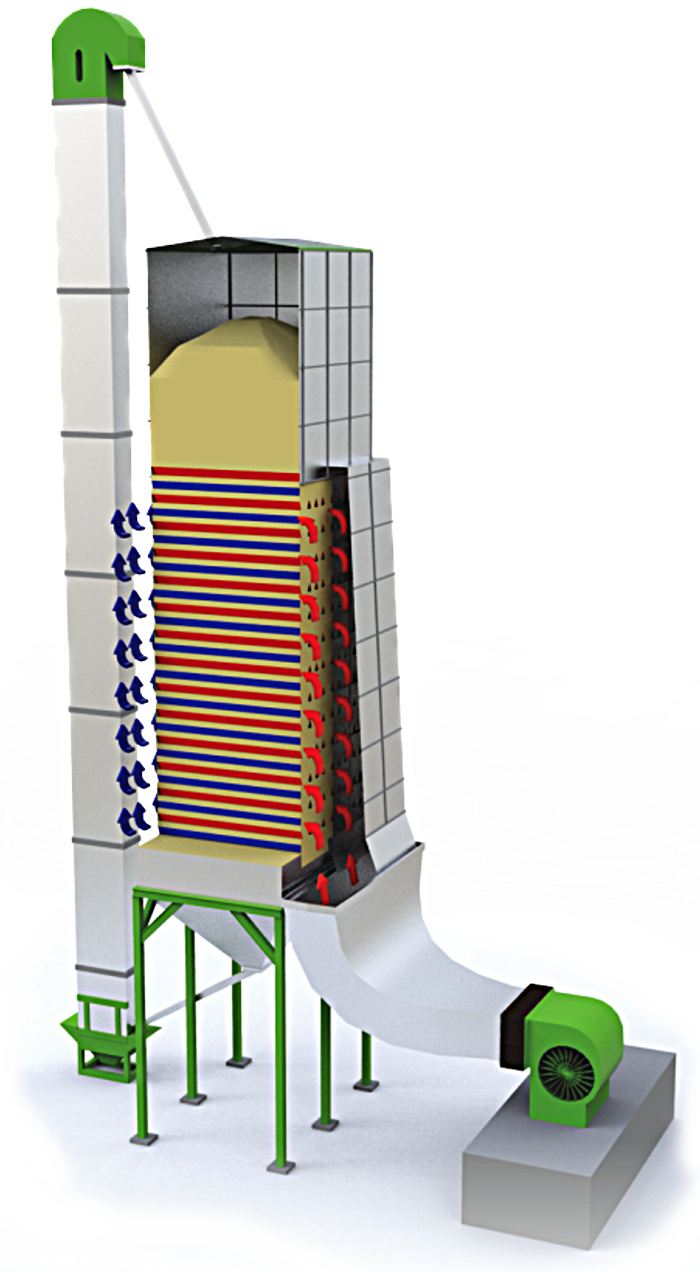

Grain enters the dryer at the top and falls into a self cleaning grain receiving chamber. This chamber also provides a means of distributing grain evenly around the dryer. The bin at the top of the dryer has a full of wet grain storage. Grain moves down” wide grain drying columns in the heat section of the dryer. Large column holding capacities result in high quality, efficiently dried grain in the drying section of the dryer.

Well-organized Elevators

The efficient and silent rectangularly profiled bucket elevator guarantees fast operations and loading/unloading of the dryer. The elevator will give many years of service: all its structures are manufactured from Stainless steel. The elevator comes equipped with a shaft-mounted geared motor: no belt changing or tightening needed. The top of the elevator contains an aspirator as standard.

Energy Efficient

Efficient designed grain dryers will help your company reduce operation costs, Maximized efficiency regarding energy and power consumption secures low operation costs together with lowest possible environmental impact.

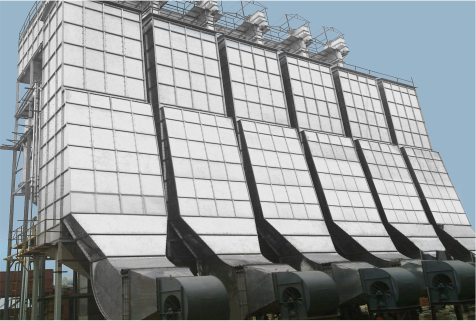

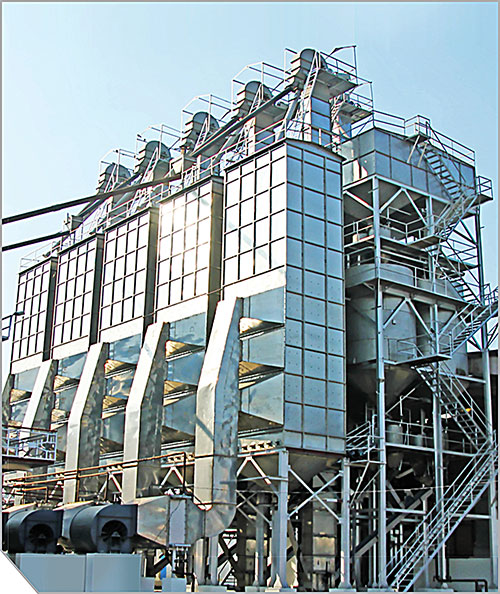

Aesthetic Design

For exterior design usages of drier outer coverage is produced by decorative bright shine brushed stainless steel. Paddy dryer to provide to move your product safely and efficiently through an effective drying process.

Adaptable ‘flow’ technology

Whether your product is wet and sticky, bulky or free-flowing we will do extensive testing to adapt your paddy dryer to provide to move your product safely and efficiently through an effective drying process.

Easy Operation & Long Life

Easy operation design, everybody can operate the dryer easily. Easy maintenance design, the operator could change the spare parts himself. Heavy-duty construction makes durability for longer operation and minimal maintenance; this ensures a long and reliable service life from indoors and outdoors.

Easy Access

Ample clearance under the dryer offers easy walk-through access and generous space for auxiliary equipment, driers are supplied with ladders and platforms for easy and safe access to vital parts of the drier.

High Capacity Dryer

| Space Requirement | 13x30 fts. |

| Power Requirement | 25 HP |

| Steam Kg/Hr. | 800 |

| Blower CFM | 25000 |

| Height of Elevator | 70 fts. |

| Buckets in Elevator | 10” |

| Height of Drier | 55 fts. |

| Loading Time | 60 min. |

| Space Requirement | 13x30 fts. |

| Power Requirement | 28 HP |

| Steam Kg/Hr. | 1100 |

| Blower CFM | 34000 |

| Height of Elevator | 75 fts. |

| Buckets in Elevator | 12” |

| Height of Drier | 60 fts. |

| Loading Time | 75 min. |

| Space Requirement | 13x30 fts. |

| Power Requirement | 35 HP |

| Steam Kg/Hr. | 1600 |

| Blower CFM | 46000 |

| Height of Elevator | 82 fts. |

| Buckets in Elevator | 12” |

| Height of Drier | 67 fts. |

| Loading Time | 90 min. |

| Space Requirement | 22x37 fts. |

| Power Requirement | 55 HP |

| Steam Kg/Hr. | 1900 |

| Blower CFM | 52000 |

| Height of Elevator | 82 fts. |

| Buckets in Elevator | 14” |

| Height of Drier | 67 fts. |

| Loading Time | 110 min. |

| Space Requirement | 24x37 fts. |

| Power Requirement | 55 HP |

| Steam Kg/Hr. | 2250 |

| Blower CFM | 62000 |

| Height of Elevator | 82 fts. |

| Buckets in Elevator | 14*2” |

| Height of Drier | 67 fts. |

| Loading Time | 130 min. |

Drying Technical Solutions

Elevators

The efficient and silent rectangularly profiled bucket elevator guarantees fast operations and loading/unloading of the dryer. The elevator will give many years of service: all its structures are manufactured from Stainless steel. The elevator comes equipped with a shaft-mounted geared motor, High tensile HR grade belting, Stainless Steel Buckets and Bolts, Heavy duty Top and Bottom and delivery pipe a are specially designed for wet paddy circulation.

Storage Bins

Maximum no. of Tied Rods Supports higher peak loads and allowing more grain to move inch storage faster than ever before. The design of storage bins increases the strength, allowing you to go taller with your grain drying system and have more flexibility in design.

Sturdy Construction

The driers consist of High-grade Stainless steel, and Heavy duty Steel Structure which ensures a great strength and concise structure. Heavy duty construction makes durability for longer operation and minimal maintenance. Drier leg extensions are available and can be easily installed as needed for clearance under the dryer.

Discharge Section

A heavy duty Multi rotors discharge gates provide work for the first-in- first-out of grain flow. Provided variable-speed motor, the unloading system’s speed can be automatically adjusted. This discharge system gives homogeneous flow, easy to clean and gently deliver it to the unloading point at the perimeter of the dryer.

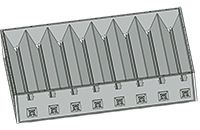

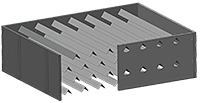

Drying Section

Homogeneous Grain Flow as number and thickness of baffles in chamber is more for smooth drying without formation of cracks in grain. All heated air must pass through the grain column resulting in total use of heated air. The dryer sections are designed to eliminate the rapid contact of the drying grain column with incoming hot air which reduces excessive grain breakage. Air baffles are Zig-Zag from row to row to maximise grain turnings during drying stages.

Air Ducts

Air Ducts for the grain and finest airflow through the dryer. The stainless steel air duct designed in such a way which provides equal and even hot air towards drier tunings during dryer stages.

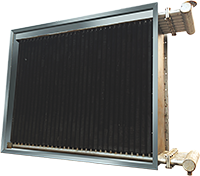

Steam Heat Exchanger

To reach the drying temperature level a steam heat exchanger is applied according to the source of steam (either Boilers or Rice Husk Furnace). The Heat Exchanger made of seamless carbon steel tube with aluminium extruded fins. Steam pressure should be around 7 kg/cm.

Centrifugal Fan

Immense air volume enables the use of low drying temperature thus minimizes internal breakage of grain. A high competence, backward curved centrifugal fan with low revolution speed ensures trouble free operation and long service life. Power is economically and fully utilized to produce the best yield.

Installed Drying Plants